製品カテゴリ

- USB スクリュー ロック ケーブル 26

- コネクタとケーブル 18

- カスタムワイヤーハーネス 33

- ハブ 47

- 電子スイッチサプライヤー 5

- USBアングルケーブル 27

- 端子アンテナ 9

- 医療用ケーブル 37

- USB4ケーブル 11

- POGOピンケーブル 10

- 防水ケーブル 28

- タイプCケーブルとアダプター 41

- USB5ケーブル 9

製品タグ

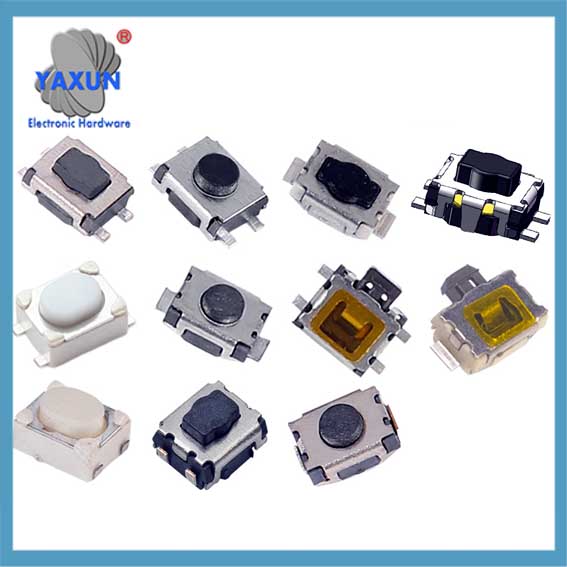

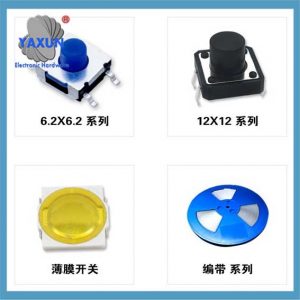

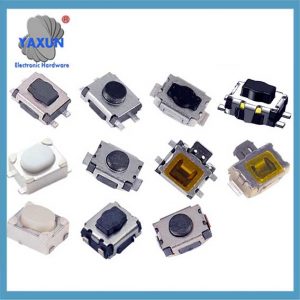

SMD/SMT 最新タクタイル スイッチ, 表面実装 PCB タクト スイッチ

タッチスイッチの品質を左右する要因: 主に保護によって決定されます, はんだ付け性, 導通信頼性, 人生, 感じる, タッチスイッチの製造工程と設置サイズ.

Tactile Switches 6 x 6 んん, 5 mm Act Height, 260 gf, 黒, Surface Mount, SPST, Surface-mount tact switches measuring 3.5mm x 2.6mm with a life expectancy of up to 500,000 cycles.

タクタイルスイッチ メンブレンスイッチ 防水スイッチ |

MD SMT 最新タクタイル スイッチ, 表面実装 PCB タクト スイッチ |

1.7H 1.8H 1.87H 1.92H 2.0H 2.5H 2.6H 2.8H 3.0H 3.5H 4.0H touch switch |

Tactile Surface Mount, PCB Tact Switch

The main specifications of tact switches are: environmentally friendly and high temperature resistant tact switches; SMD tact switches; plug-in tact switches; side plug-in tact switches; large/medium/small turtle-shaped tact switches; 2*4 tact switches; 3*3 tact switches; 3.7*3.7*0.3 imported tact switches; 4*4*1.5/1.6/17mm tact switches; 3*6*4.3/5.0mm automotive tact switches; 4*6*2.6 tact switch; 4.5*4.5*3.8/4.8/5/0/6/7/8/9 SMD tact switch; plug-in tact switch; side three-solution tact switch; 6*6*4.3/5.0/5.5/6/7/8/9/9.5/10/11/12/13/14/15/16/17/18/19/20/21/26mm tact switch; SMD tact switch; plug-in tact switch; 6.2*6.2*2.5/2.7/3.1/3.4 tact switch; 12*12*4.3/5.0/5.5/6/7/8/9/10/11/12/13/14/15/16/17/18/19/20/21/22/23mm tact switch. 6*6 series waterproof touch switch; 8*8 series waterproof touch switch; 10*10 series waterproof touch switch; 12*12 series waterproof touch switch.

タッチスイッチの品質を左右する要因: 主に保護によって決定されます, はんだ付け性, 導通信頼性, 人生, 感じる, タッチスイッチの製造工程と設置サイズ.

1. Pin substrate: The pin substrate of the touch switch is brass or phosphor copper (low-grade iron). In order to reduce the contact resistance, the pin is basically silver-plated, because silver will oxidize when it encounters SO2 gas in the air, which directly affects the solderability and contact resistance of the switch. したがって, high-quality touch switches must first control the silver plating thickness and silver plating process of the pin substrate. The order of silver plating in the market is as follows:

Silver plating thickness: above 0.3um (post-silver), 0.2um (thin silver), 0.1um (white plating).

Silver plating process: substrate pre-nickel plating and then silver plating, substrate pre-copper plating and then silver plating, substrate direct silver plating.

It is very important whether the substrate is treated with a protective agent after silver plating or whether the switch has dust and water resistance. さもないと, even with the best silver plating, the switch will be oxidized.

2. The key factor affecting the conduction reliability is the structure of the contact point. Because the function of the touch switch is to make the contact point and the spring contact and conduct, the larger the contact surface of the contact point, より良い. The contact surface is determined by the structure. There are roughly three types of structures on the market, and the order of advantages and disadvantages is as follows: “O-type contact”, “slotted contact”, “flat bubble contact”.

3. Life and feel: Life and feel are determined by the stroke of the touch switch and the coordination of the spring. The shorter the stroke, the lighter the sound and the longer the life, and the longer the stroke, the opposite. Under the condition of fixed spring technology, the life of the touch switch is mainly determined by the stroke or sound. 加えて, the key factor that determines the life of the spring is still the stamping technology. The stamping technology of Japan and Taiwan is now very popular in China. したがって, under the condition of technological improvement, the requirements for materials are whether imported materials are reduced. 例えば, there are four main types of 160gf shrapnel life in the market: について 50,000 回 (domestic phosphor copper or relatively backward stamping technology), について 100,000 回, より多い 200,000 回 (stainless steel), そして 300,000 回.

4. Production process: After having accessories, the final factor that affects the quality is the assembly process, which depends on factors such as the management ability of the production company, the quality intention of employees, and the quality assurance ability. The quality of the final product with different assurance capabilities is definitely different. Now the market assembly methods include manual and machine. Because the current automation capabilities are still being improved, each has its advantages and disadvantages: the cost of machine assembly is low but the product quality is low, and the cost of manual assembly is high but the quality is also high.

5. Factory inspection: The methods and items of factory inspection also affect the quality of the final touch switch. 例えば, whether the appearance, 感じる, conduction, resistance and other items are sampled or fully inspected. 例えば, the scrap rate required by some large factories is measured by PPM or zero defects. It is necessary to set up sampling inspection or quality inspection after setting up full inspection in factory inspection.

お問い合わせ

メールを待っています, 以内に返信させていただきます 12 必要な貴重な情報を何時間も入手できる.

English

English العربية

العربية bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά עברית

עברית Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska தமிழ்

தமிழ் ภาษาไทย

ภาษาไทย Tiếng Việt

Tiếng Việt