Danh mục sản phẩm

Thẻ sản phẩm

Chức năng và ứng dụng của cụm cáp dẹt

Cụm cáp phẳng được sử dụng trong các ứng dụng điện và điện tử khác nhau để cung cấp hệ thống dây điện hiệu quả và có tổ chức. Họ cung cấp một cách nhỏ gọn và linh hoạt để quản lý nhiều dây dẫn, thường được sử dụng trong điện tử tiêu dùng, thiết bị công nghiệp, và hơn thế nữa. Cáp dẹt, còn được gọi là cáp ruy băng hoặc cáp phẳng linh hoạt, được đặc trưng bởi căn hộ của họ, hình dạng giống như dải băng và mang lại những lợi thế như tiết kiệm không gian, thiết kế nhẹ, và cải thiện tính linh hoạt so với cáp tròn.

Cụm cáp phẳng được sử dụng trong các ứng dụng điện và điện tử khác nhau để cung cấp hệ thống dây điện hiệu quả và có tổ chức. Họ cung cấp một cách nhỏ gọn và linh hoạt để quản lý nhiều dây dẫn, thường được sử dụng trong điện tử tiêu dùng, thiết bị công nghiệp, và hơn thế nữa. Cáp dẹt, còn được gọi là cáp ruy băng hoặc cáp phẳng linh hoạt, được đặc trưng bởi căn hộ của họ, hình dạng giống như dải băng và mang lại những lợi thế như tiết kiệm không gian, thiết kế nhẹ, và cải thiện tính linh hoạt so với cáp tròn.

Flat cable assemblies play a key role in many industrial fields with their unique structural and performance advantages. The following is a detailed description from the two dimensions of function and application:

6-pin Flat Flex Cable Assembly Solder Lug to Solder Lug |

2.54mm Sân 50 Ghim 50 Cách kết nối F-F IDC Flat Rainbow Ribbon |

FACILA25P70-221133G 25 Position Flat Flex Cable Assembly 2.76″ |

1. Functional characteristics

Space optimization and efficient wiring

The parallel conductor arrangement design of flat cables significantly reduces space occupancy, especially in small equipment (such as industrial robots and smart terminals), which can achieve efficient wiring and improve space utilization.

Dynamic adaptability and durability

It has high-frequency bending ability (up to hundreds of thousands of times) and tensile strength to adapt to the repeated movement requirements of mobile equipment (such as cranes, cranes), while wear-resistant, oil-resistant and corrosion-resistant materials enhance environmental adaptability.

Signal transmission stability

Low noise and anti-electromagnetic interference characteristics ensure the integrity of high-frequency signal transmission and meet the precision signal transmission requirements of medical equipment, automotive electronics and other scenarios.

Customized design

Supports color-coded core wires, grouped arrangement (straight/plum blossom shape) and additional load-bearing components (such as galvanized steel wire ropes) for easy identification and enhanced mechanical strength.

Adaptability to extreme environments

High-temperature resistant fiber braiding or special material sheath makes it suitable for high-temperature radiation environments in aerospace and industrial low-temperature scenarios of -40℃~70℃.

Types of Flat Cable Assemblies:

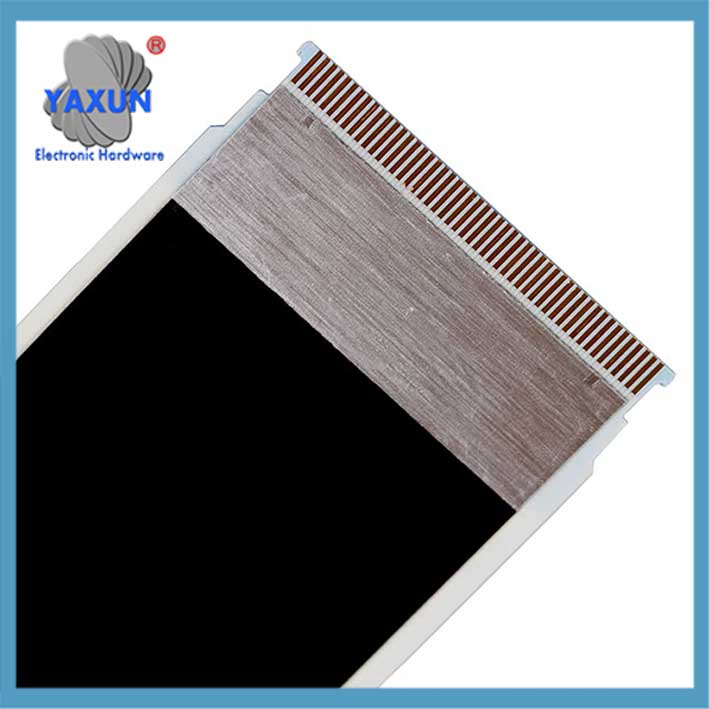

Flat Ribbon Cables:

These are the most common type and are made of multiple parallel conductors.

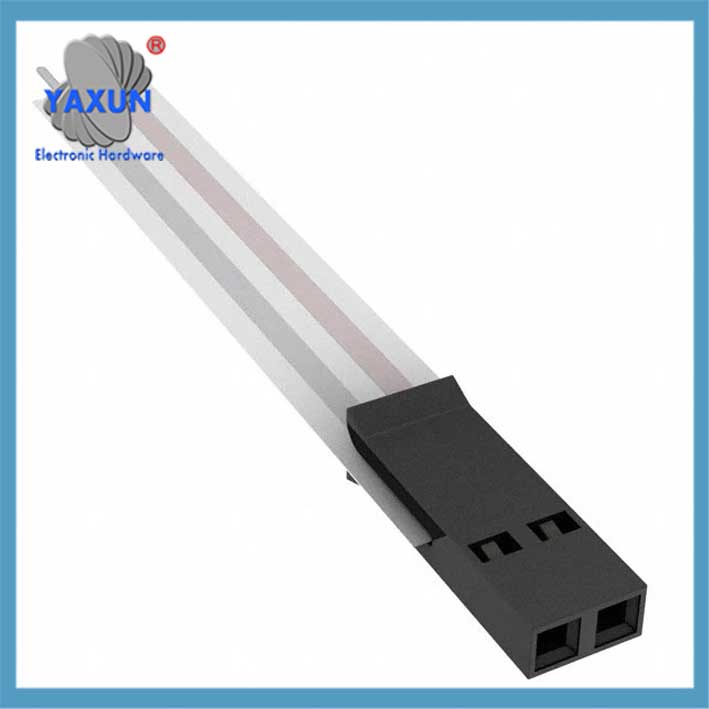

Flat Flexible Cables (FFC):

These are designed for flexibility and can be used in applications where the cable needs to be bent or folded.

Flat Printed Circuits (FPC):

These are similar to FFCs but have printed circuits on the flexible substrate.

Space Saving:

Flat cables have a higher packing density than round cables, making them ideal for applications with limited space.

Lightweight:

Flat cables are lighter than round cables due to their design and reduced need for supports.

Flexible:

They can bend more easily and conform to tight spaces, making them suitable for various applications.

Improved Reliability:

Flat ribbon cables can improve reliability in certain applications due to their design and construction.

Cost-Effective:

They can be cost-effective due to material and manufacturing advantages.

Customization:

Flat cable assemblies can be customized for specific applications, such as folding or direct soldering.

A9BAG-0202F 2-pin flat flex cable assembly |

JF08R0R041040UA Cụm cáp mềm phẳng 41 chân |

AFFC-050-30-076-11 FFC,FPC Cable |

2. Kịch bản ứng dụng

Consumer electronics

High-speed interconnection between motherboards and display screens and camera modules of smart terminals such as mobile phones and tablets, helping to make the equipment lightweight and thin.

Automotive industry

Supports the transformation of electric vehicles and 48V systems, connects ECU, ADAS, and in-vehicle entertainment equipment, and meets automotive-grade temperature resistance and vibration resistance standards.

Tự động hóa công nghiệp

As the electrical hub of industrial robots and PLC control systems, it connects sensors and actuators to improve production line stability and maintenance efficiency.

Heavy mobile equipment

The power and control connections of equipment such as gantry cranes and cranes rely on its high flexibility and tensile strength to adapt to frequent movement and bending conditions.

Medical and aerospace

Medical imaging equipment relies on its low-noise transmission, and spacecraft electronic systems use special flat cables that are resistant to high temperatures/radiation to achieve stable connections in extreme environments.

Dynamic connection scenario

Using ultrasonic welding technology, reliable connection with components such as busbars is achieved, which is suitable for electrical interfaces that need to be moved frequently.

Consumer Electronics: Used in devices like 3D printers, copy machines, and scanners.

Industrial Equipment: Employed in robots, robotic arms, and automation systems.

ô tô: Used in car infotainment systems, switch rotary connectors, và các ứng dụng khác.

Medical Devices: Used in medical displays and other equipment.

Aerospace: Used in aircraft for various connections, including displays and infra-red cameras.

Data Centers and Server Rooms: Used for wiring and interconnection within these environments.

Flat Panel Displays: Used in various displays, including those in televisions and monitors.

3. Technology evolution trend

With the flattening of automobile architecture and the upgrading of industrial automation, flat cable assemblies will further integrate flexible printed circuit technology to promote the miniaturization and intelligent development of connection systems.

The assembly process typically involves connecting connectors to the ends of the flat ribbon cable and may include additional components or protective coverings. Some flat cable assemblies can be assembled with off-the-shelf components, while others require more specialized fabrication, says Epec.

Tóm lại, flat cable assemblies offer a versatile and efficient solution for wiring and interconnection in a wide range of applications. Their flexibility, space-saving design, and reliability make them a popular choice for both consumer and industrial applications.

Liên hệ với chúng tôi

Đang chờ email của bạn, chúng tôi sẽ trả lời bạn trong vòng 12 giờ với thông tin có giá trị bạn cần.

English

English العربية

العربية bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Dansk

Dansk Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά עברית

עברית Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska தமிழ்

தமிழ் ภาษาไทย

ภาษาไทย Tiếng Việt

Tiếng Việt